Factory Supply Aluminum Extrusion E Channel

| Prix unitaire: | 2885~3620 USD |

|---|---|

| Quantité de commande minimum: | 1 Ton |

| Détails d'emballage: | Our Exporting Standard Packaging: PE Foam+Plastic Bag+Carton Box+Pallet; PE Foam+Plastic Bag+Wooden Box. |

|---|---|

| productivité: | 50000 per month |

| marque: | OEM |

| transport: | Ocean,Land,Air,BY Express |

| Lieu d'origine: | Jiangsu, China |

| Capacité d'approvisionnement: | 50000 per month |

| Certificats : | International Automotive Task Force |

| Hafen: | ShangHai.China |

Click on the follow link to find out more information: https://www.tongdetrade.com/aluminum-profile-extrusions-1675921/

Info de Compagnie

- Nom de la compagnie: JIANGSU TONGDE INTERNATIONAL TRADE CO.LTD.

- représentant: ENBO CHENG

- Produit / Service: PRODUITS MÉTALLIQUES , PIÈCES D'ESTAMPAGE , PIÈCES DE MOULAGE , Usinage CNC , Fabrication de tôles , Filature de métal

- Capital: 2000000RMB

- Année d'Etablissement: 2018

- Volume total annuel des ventes (en millions de US $): US$5 Million - US$10 Million

- Pourcentage des exportations: 61% - 70%

- Total volume d'achat annuel (en millions de US $): US$50 Million - US$100 Million

- Nombre de Lignes de Production: 12

- NombrNombre du Personnel de R&e du Personnel de R&D: 11 -20 People

- Nombre du Personnel de QC: 11 -20 People

- Service d'OEM fourni: yes

- Superficie de l'Usine (mètre carré): 5,000-10,000 square meters

- Adresse de l'Usine: 江苏省泰州市靖江市靖江开发区城南园区东进路8号。

- Personne À Contacter: Mr. Davidcheng

- Numéro De Téléphone: +86-0523-18921730790

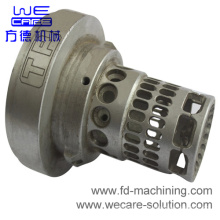

Premium Related Products

autres produits

Produits phares

Produits d'exportation à haute demande fonte en fonte grise achetez directement depuis le fabricant de la ChineProduits de haute qualité spécialisés en fonte de fonte spécialisés en alibabaLe fournisseur d'Alibaba vend le nouveau produit de chariot élévateur de nouveaux produits chauds pour 2016 États-UnisChine fournisseur professionnel pièces de machines centrales, machines outils de pièces industriellesPièces de machines en acierOEM coquille de fonte dents de ferCrochet de remorquage en acier forgéDensen unnormalized OEM mini piston hydrauliquePièces d'estampage à chaud non métalliques de haute qualité OEMBride blindée OEM personnaliséeNouveau tube de cylindre hydraulique OEM non normalisé DensenRaccords de tuyauterie en acier inoxydablePièces auto personnalisées fabriquées en ChineRaccords de tuyaux en acier inoxydable fabriqués en ChinePièces en acier moulé personnalisées de haute qualité fabriquées en ChineUnion de marteau avec fil pour champs pétrolifères